Main Sizes

50~120000Nm3/h Air Separation Plants; 50~40000Nm3/h High-purity Nitrogen Air Separation Plants; 100~1000TPD Oxygen and Nitrogen Liquefaction Plants; 100~1000TPD Liquid Air Separation Plants Utilizing LNG Cold Energy;Helium, neon, krypton and xenon extraction plants.

>Technical Features

On the basis of introducing and learning the advanced technology from home and abroad and independent research & development, SASPG has developed large air separation plant of capacity of hundred thousand Nm3/h. SASPG could offer the optimized process according to client’s different requirements which includes low pressure molecular sieve adsorption (vertical radial flow) process, medium /low pressure booster turbo-expander cold generation process, product oxygen internal/external compression process, product nitrogen internal/external compression process, air/nitrogen pressurizing recycling process, liquid expander cold regeneration process, structured packing rectification process, without-using-hydrogen argon production process, rare gas full-recovery process and its automatic off-design load and optimizing control technology.The oxygen recovery rate reaches more than 99.6% and the argon recovery up to 80% while the lowest specific power consumption of oxygen is 0.34kw.h/Nm3. A number of independent innovation technology has been successfully applied in 40000~60000 Nm3/h air separation plants. SASPG has made eye-catching progress in large and medium-sized air separation plant design and manufacturing and has obtained well-proven, complete and advanced air separation technologies with its own special characteristics.

|

| 2×52000Nm3/h Air Separation Plants |

|

| 2×40000Nm3/h Air Separation Plant |

|

| 2×43000Nm3/h Air Separation Plant |

|

| 2×35000Nm3/h Air Separation Plant |

|

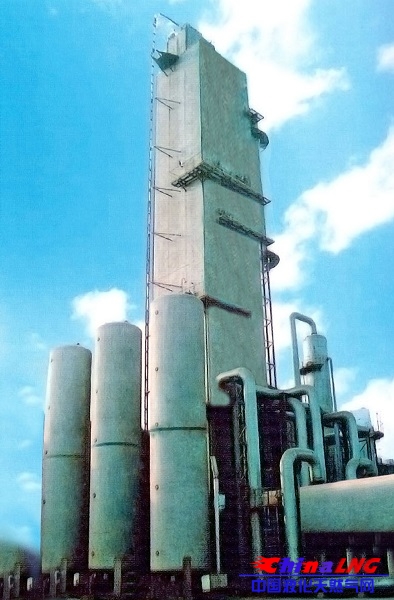

| 480T/d Liquefier |

|

| 15000Nm3/h Air Separation Plant exported to Turkey |

|

| 10000m3/h High-purity Nitrogen Air Separation Plant |

|

| 17000Nm3/h Air Separation Plant for Iron & Steel Group |