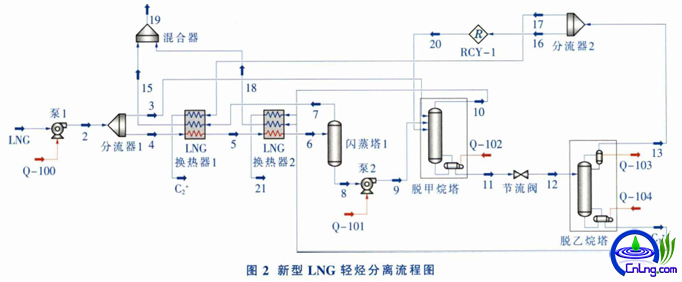

摘要根据LNG中组分的特点,借助于模拟软件HYSYS,通过对现有轻烃分离流程进行分析对比,对其换热网络进行模拟优化设计。以某一大型LNG接收站为例,设计了一种新型的利用LNG冷能的轻烃分离工艺流程,采用闪蒸塔闪蒸分离出36%的甲烷气体,从而减少了脱甲烷塔的负荷,降低了塔的投资和能耗。脱甲烷塔在高压状态下进行甲烷的分离,分离出的甲烷气体和闪蒸塔分离出的甲烷气体混合后经过LNG换热器进行液化。脱乙烷塔在低压的状态下进行乙烷的分离,分离出的乙烷一小部分用来循环利用,剩余的气体乙烷通过LNG换热器进行液化。通过模拟计算和参数优化,与经典工艺相比,该新型流程的甲烷物质的量分数为98.34%,乙烷的分离率为98.29%,C3+中LPG分离率为96.21%。分离得到较高纯度的甲烷和乙烷可以分别作为民用燃料气和乙烯裂解原料使用。According to the characteristics of components in LNG, the existing light hydrocarbon separation process was analyzed and compared with the help of simulation software HYSYS,and the heat transfer network was simulated and optimized.Taking a large LNG receiving station as an example,this paper designs a new light hydrocarbon separation process using LNG cold energy,which uses a flash column to separate 36%of the methane gas,thus reducing the load of demethanizer and reducing its investment and energy consumption.The demethanizer separates methane under high pressure,and the methane gas separated is mixed with the methane gas separated from the flash column and then liquefied through LNG heat exchanger.The deetha-nizer is used to separate ethane at low pressure.A small portion of the separated ethane is used for recy-cling,and the remaining gas ethane is liquefied through the LNG heat exchanger.Through simulation calcula-tion and parameter optimization,the methane molar fraction,ethane separation rate and LPG separation rate in C3+of this new process are 98.34%,98.29%,and 96.21% respectively,compared with the classical process.The high-purity methane and ethane separated can be used as domestic fuel gas and ethylene cracking raw material respectively.