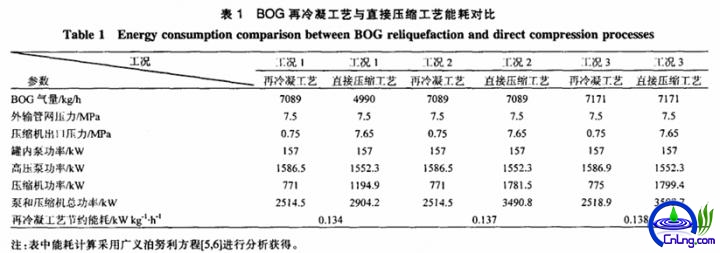

摘要对LNG(液化天然气)接收站BOG(蒸发气)气体主要的两种不同回收方式,即再冷凝工艺和直接压缩工艺进行了能耗分析,指出再冷凝工艺更为节能;以进一步节省工艺能耗为目的,对现有BOG再冷凝工艺进行了优化。运用ASPEN流程模拟软件对BOG压缩机进出口压力、BOG温度及物料比等影响BOG再冷凝工艺能耗的运行参数的分析,提出了利用高压LNG对增压后的BOG进行预冷,降低物料比从而降低BOG压缩机能耗的工艺流程。优化后的BOG再冷凝工艺节能效果显著,较原工艺可节约BOG压缩机能量消耗31.4%。Energy consumption of two different processes, reliquefaction and direct compression, for recovering boil off gas (BOG) gas of LNG terminals were analyzed. The results showed that the reliquefaction process was more energy-saving. To save more energy, the existing BOG reliquefaction process was optimized. ASPEN process simulation software was used to analyze the operating parameters including BOG compressor inlet and outlet pressures, BOG temperature and material ratio that may affect the energy consumption of the BOG reliquefaction process. Based on the analysis results, an improved process was proposed, in which the high-pressurized LNG was used to precool the pressurized BOG to reduce the stm't material ratio, so as to reduce the energy consumption required for the compressors. The improved process could reduce compressor energy consumption by 31.4% comparing to the original process.

关键词LNG 接收站 BOG气体 再冷凝 功耗 工艺改进LNG terminal boil off gas BOG reliquefaction energy consumption process optimization