免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

摘要:该矿位于新疆哈密市西南84公里处戈壁荒漠中,是国家战略“疆电外送”哈密南--郑州正负800千伏特高压直流输电工程的配套建设项目,是国家规划哈密煤电外送基地的主力煤矿之一,也是新疆维吾尔自治区“十三五”重点规划的露天煤矿。目前主要担负着花园电厂、大南湖电厂..

|

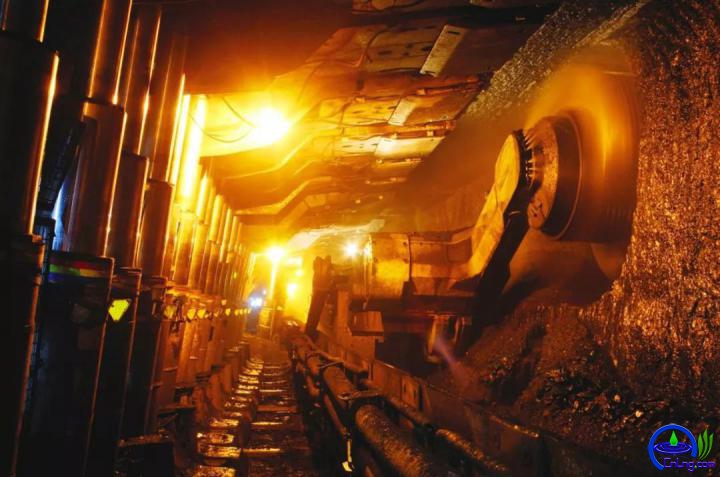

该矿位于新疆哈密市西南84公里处戈壁荒漠中,是国家战略“疆电外送”哈密南--郑州正负800千伏特高压直流输电工程的配套建设项目,是国家规划哈密煤电外送基地的主力煤矿之一,也是新疆维吾尔自治区“十三五”重点规划的露天煤矿。目前主要担负着花园电厂、大南湖电厂等电厂的供煤任务和煤炭外运任务。

国内首台通用运输场景露天矿用无人运输机器人就在矿区投运,煤矿先后投入使用了无人驾驶宽体车、矿山运输无人驾驶机器人,不断推进数字化矿山建设。 按照公司之前的计划,预计到2023年年底实现煤矿智能化技术及建设100%全覆盖,实现采煤工作面、掘进工作面、选煤厂100%智能化,实现固定岗位100%无人值守,为国家智慧矿山建设树立典范。 据了解,该矿自2013年开工建设以来,累计完成投资12.4亿元,2020年被列入国家“绿色矿山”名录。智能化建设的推进无疑给煤矿产能核增奠定了坚实的基础。 The mine is located in the Gobi desert, 84 kilometers southwest of Hami City, Xinjiang. It is a supporting construction project of the national strategic "Xinjiang power transmission" Hami South - Zhengzhou plus or minus 800 kV UHVDC transmission project, one of the main coal mines of the national planning of Hami coal power transmission base, and also an open-pit coal mine in the "13th Five-Year Plan" of Xinjiang Uygur Autonomous Region. At present, it is mainly responsible for the coal supply and coal transport tasks of the Garden power plant, Danan Lake Power Plant and other power plants. In recent years, the national energy Group Guoshen Company Dananhu second mine insists on intelligent construction as an important direction of development. Since its completion in 2013, Dananhu No. 2 Mine has continued to promote the construction of intelligent mines, and has built intelligent systems such as vehicle collision prevention, overspeed warning, coal seam spontaneous combustion warning, video surveillance, inspection robots, and so on. It has realized the early warning and monitoring of coal seam high temperature and heat, the full coverage of production sites, and the continuous inspection of power substation, boost station and other places. The first unmanned transportation robot for open-pit mining in the domestic general transportation scene was put into operation in the mining area, and the coal mine has successively put into use the unmanned wide-body vehicle and the unmanned robot for mining transportation to continuously promote the construction of the digital mine. According to the company's previous plan, it is expected to achieve 100% full coverage of intelligent technology and construction in coal mines by the end of 2023, achieve 100% intelligent coal mining face, driving face, coal preparation plant, and achieve 100% unattended fixed positions, setting a model for the construction of national smart mines. It is understood that since the construction of the mine began in 2013, the cumulative investment of 1.24 billion yuan has been completed, and it is included in the national "green mine" list in 2020. The promotion of intelligent construction has undoubtedly laid a solid foundation for the nuclear increase of coal mine production capacity. |

近年来,国家能源集团国神公司大南湖二矿坚持将智能化建设作为发展的重要方向。大南湖二矿自2013年建成以来,持续推进智能化矿山建设,已建有车辆防碰撞、超速预警、煤层自燃预警、视频监控、巡检机器人等智能化系统,实现了煤层高温发热预警监测,生产场所全覆盖监控,变电所、升压站等场所不间断巡检。

近年来,国家能源集团国神公司大南湖二矿坚持将智能化建设作为发展的重要方向。大南湖二矿自2013年建成以来,持续推进智能化矿山建设,已建有车辆防碰撞、超速预警、煤层自燃预警、视频监控、巡检机器人等智能化系统,实现了煤层高温发热预警监测,生产场所全覆盖监控,变电所、升压站等场所不间断巡检。