免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

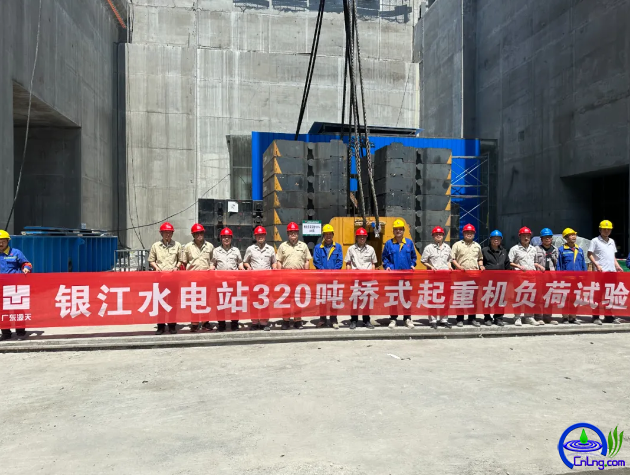

摘要:4月14日,由源天公司承建、西南公司负责施工的四川省攀枝花市金沙江银江水电站机电安装与调试工程CⅣ标段320吨桥机的负荷试验圆满完成,标志着项目进入设备安装全面施工阶段。试验严格遵循有关规程、规范和试验大纲,试验技术人员和现场工作人员紧密配合,开展了75%..

|

4月14日,由源天公司承建、西南公司负责施工的四川省攀枝花市金沙江银江水电站机电安装与调试工程CⅣ标段320吨桥机的负荷试验圆满完成,标志着项目进入设备安装全面施工阶段。

此次试验的圆满完成,为后续大件设备吊装、材料运输转运提供了成功范例,同时也为接下来主轴、导水机构等设备的吊装施工打下了坚实基础。 On April 14, the load test of 320 tons bridge in the section C IV of the electromechanical installation and commissioning project of Jinshajiang Yinjiang Hydropower Station in Panzhihua City, Sichuan Province, which was undertaken by Yuantian Company and constructed by Southwest Company, was successfully completed, marking that the project entered the stage of comprehensive equipment installation and construction. The test strictly followed the relevant procedures, specifications and test program, and the test technicians and field staff cooperated closely to carry out the dynamic load test of 75%, 100% and 110% of the rated load and the static load test of 125% of the rated load. The test efficiency was improved by using reusable hanging baskets and crane standard counterweights as loads. The safety of the test is ensured. After the completion of the test, the counterweight block is immediately transferred to the truck crane for continued use, and the use of counterweight block counterweight reduces the input of manpower and material resources, greatly saving the test cost and test time. Finally, the bridge operated smoothly under the premise of the maximum lifting load of 400 tons and 125% static load, passed the acceptance at one time, and was fully affirmed by the on-site owners and supervision units. The successful completion of this test provides a successful example for the subsequent hoisting of large equipment and material transportation, and also lays a solid foundation for the hoisting construction of the following equipment such as the main shaft and water guide mechanism. |