免职声明:本网站为公益性网站,部分信息来自网络,如果涉及贵网站的知识产权,请及时反馈,我们承诺第一时间删除!

This website is a public welfare website, part of the information from the Internet, if it involves the intellectual property rights of your website, please timely feedback, we promise to delete the first time.

电话Tel: 19550540085: QQ号: 929496072 or 邮箱Email: Lng@vip.qq.com

摘要:在工艺流程上,首先,硫化氢的沼气气体进入洗涤塔,在塔内与混合中碱产生反应并从沼气中初步脱除硫化氢。接下来,洗涤塔吸收液流至塔底,进入生物反应器。在反应器底部有空气分布系统,给微生物提供氧气,通过微生物细胞壁上的酶将反应器中的硫化物转化为单质硫,单..

|

在工艺流程上,首先,硫化氢的沼气气体进入洗涤塔,在塔内与混合中碱产生反应并从沼气中初步脱除硫化氢。接下来,洗涤塔吸收液流至塔底,进入生物反应器。在反应器底部有空气分布系统,给微生物提供氧气,通过微生物细胞壁上的酶将反应器中的硫化物转化为单质硫,单质硫在分离器中分离,完成再次脱硫,同时碱液得到再生。然后利用微生物在新陈代谢的过程中吸收硫元素,从而达到深度脱硫的目的,脱硫效率高达99%以上。

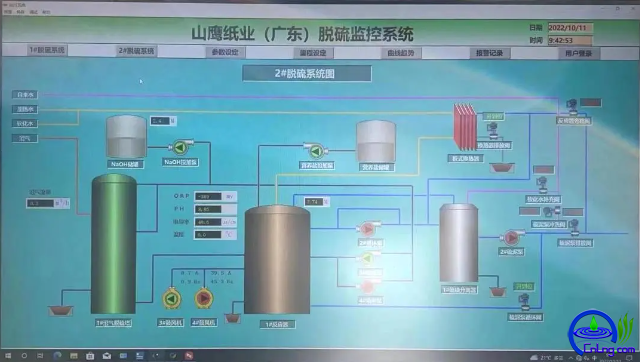

In the process, first of all, the methane gas of hydrogen sulfide enters the scrubber, reacts with the mixed alkali in the tower and initially removes hydrogen sulfide from the methane. Next, the scrubber absorption liquid flows to the bottom of the tower and into the bioreactor. There is an air distribution system at the bottom of the reactor to provide oxygen to the microorganisms, and the sulfur in the reactor is converted into elemental sulfur by enzymes on the microbial cell wall. The elemental sulfur is separated in the separator to complete the re-desulfurization, and the lye is regenerated. Then the use of microorganisms in the process of metabolism to absorb sulfur elements, so as to achieve the purpose of deep desulfurization, desulfurization efficiency of more than 99%. Shanghai Environmental Protection Engineering Co., LTD., a subsidiary of Shanghai Electric, applied biogas biological wet desulfurization technology to the papermaking wastewater treatment project of Shanying Paper (Guangdong) Co., LTD., to desulfurize the biogas generated during the anaerobic treatment of its papermaking wastewater, so as to reduce the concentration of hydrogen sulfide in the biogas and thus reduce the concentration of hydrogen sulfide in the biogas fed into the generator. While extending the service life of the generator spark plug and other components, it ensures that the sulfur dioxide in the flue gas emitted from the power generation fully meets the emission requirements. Biogas after desulfurization can be used to generate electricity, reduce the cost of electricity in the production process, and at the same time, reduce the dependence on fossil fuels, reduce carbon dioxide emissions, and contribute to the realization of the "dual carbon" goal. |